FCP Runner Plastic – QCR Compatible Profile

Price range: $61.00 through $78.00

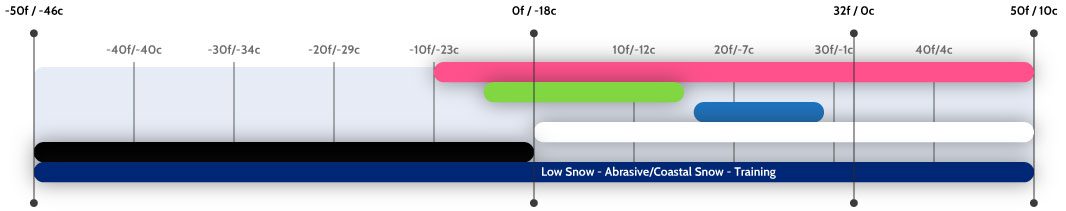

WHITE: The WHITE FCP Runner Plastic is made of a virgin UHMW plastic that is the most versatile and widely used plastic. It offers excellent glide from 0 degrees F to 50 degrees F (-18 degrees C to 10 degrees C).

HD BLACK: The HIGH DENSITY BLACK FCP Runner Plastic is the traditional High Density Black plastic that has been used for decades in both QCR plastics and our FCP plastics line. We recommend use at 0 degrees F (-18 degrees C) and below.

DARK BLUE: The DARK BLUE FCP Runner Plastic is a UHMW T88-2 product that is best suited for training, low snow conditions and coastal snow that may be very abrasive. The T882 product features an additive of microscopic glass beads which make this plastic 4 times more abrasive resistant than other UHMW plastics.

LIGHT BLUE: The LIGHT BLUE FCP Runner Plastic is one of our two wax impregnated plastics. It is made of the same product used in the ski and snowboard industries worldwide. We add SWIX medium range temperature wax to add lubrication with maximum glide between 16 degrees F (-8 degrees C) and 29 degrees F (-2 degrees C).

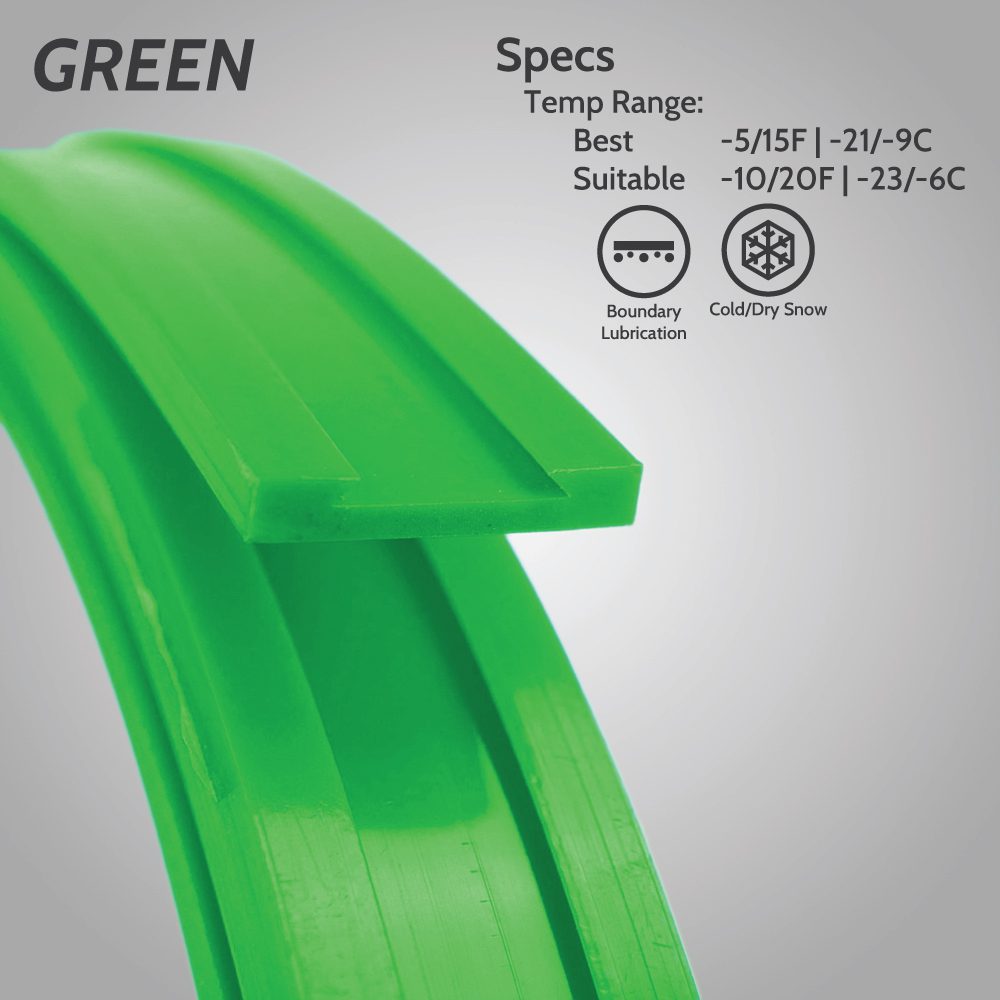

GREEN: The GREEN FCP Runner Plastic is the second of our wax impregnated plastics. Same attributes as the light blue but with a cold weather temperature wax, making it glide best between -5 degrees F (-21 degrees C) and 15 degrees (-9 degrees C).

PINK: The PINK FCP Runner Plastic is our newest addition to our premium line of runner plastics and is by far the most versatile and slipperiest in one. We have used the traditional virgin UHMW plastic and saturated with Fluoroguard, which is the additive in our ever-so-popular red FCP plastic. We’ve also added a second oil (Silane) to work in conjunction with each other to create the slickest additive on earth. Not only has the increase in Silane lowered the coefficient of friction but now it has improved the range of temperature (-10 F to 50 F). The Silane additive is chemically bonded to the Fluoroguard and in turn, the Silane chemically bonds to the plastic. This added feature helps to resist the removal of the oils from the plastic as it slides over the snow. Our early feedback from this product is showing it to be noticeably the fastest plastic in the FCP line.

BLACK with GRAPHITE: The BLACK with GRAPHITE FCP Runner Plastic is an entirely different plastic that is made specifically for the individuals who wish to wax their runners. This plastic has a high amount of carbon graphite included in the plastic to create a waxable base. When this plastic is scraped or stoneground, the particles of graphite fall out, resulting in a very porous base for the wax to seep into and adhere. This plastic is only to be used for waxing before it is used for racing. This plastic also has identical properties to the popular P-Tex plastics. We have seen an enormous increase in this type of plastic used in the last several years, as waxing has become incredibly popular.

Reviews

There are no reviews yet.